The Great Convergence of Quality, Manufacturing, and Intelligence

An Overview of 2026 Life Sciences Industry Trends

Webinar | Revolutionising Training in Regulated Industries

In regulated industries such as pharmaceuticals, biotechnology, and medical devices, training is not just a compliance requirement, it plays a critical role in operational safety, quality outcomes, and workforce readiness. Yet many organisations still rely on traditional approaches such as slide decks, SOP-heavy learning, and static e-learning...

5 Critical Medical Device Quality Trends for Compliance & Innovation

For medical device quality leaders, 2026 is the year the baseline for excellence is redrawn. The long-discussed digital transformation of quality is no longer a future concept but the new operational reality, codified in regulation. The go-live of the U.S. Food and Drug Administration’s (FDA) QMSR is the primary catalyst, yet it arrives alongside...

Supporting Medical Device Companies with Internal Audits

For more than 35 years, SeerPharma has partnered with organisations involved in the supply, manufacture, and distribution of Medical Devices and In Vitro Diagnostics (IVDs) across the Asia-Pacific region.

Our team supports companies that design, develop, and manufacture medical devices and IVDs across of all classifications, helping ensure their...

Webinar | Navigating Global Compliance: A Beginner’s Guide to MDSAP

Entering the medical device industry is an exciting venture—but it comes with a maze of regulatory requirements that can feel overwhelming, especially for startups and new manufacturers. One acronym you’ll encounter early and often is MDSAP: the Medical Device Single Audit Program.

By 2030, it is projected that over 60% of the global population will reside in the Asia-Pacific region, with one in four individuals aged 60 or older1. This demographic shift, coupled with rising healthcare costs, an increase in chronic diseases, and a more discerning healthcare consumer base, is driving exceptional growth in the region’s...

2025 Pharma and Medical Device Trends for Manufacturing Leaders

The power to control one’s health is shifting more each day from life sciences companies and healthcare organisations to the consumers themselves. Never have consumers had so many options for personalised therapies or greater control over their well-being.

Conducting a Mock FDA Audit of Medical Device Manufacturer (Singapore)

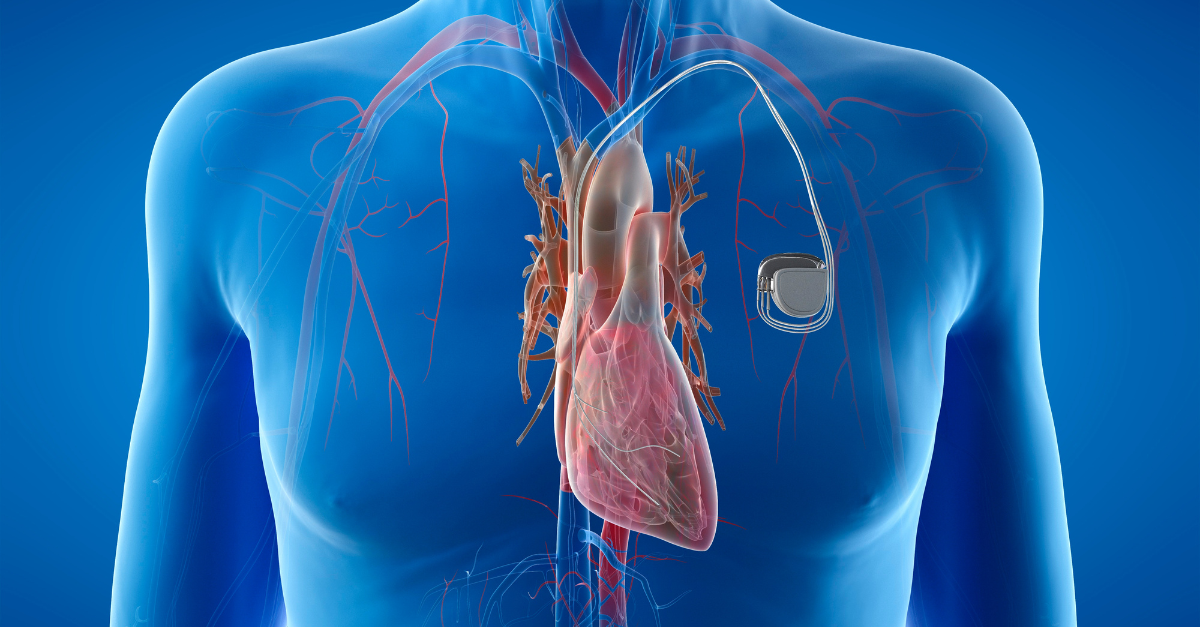

A multinational manufacturer of cardiovascular devices recently engaged SeerPharma to conduct a comprehensive mock US FDA audit of their operations in Singapore. The audit was conducted against US FDA 21 CFR Part 820 – Quality System Regulation (21 CFR 820). SeerPharma reviewed relevant documentation remotely and then spent three days on-site...

The inclusion of medical devices onto the Therapeutic Goods Administration's (TGA’s) Australian Register of Therapeutic Goods (ARTG) requires manufacturers to demonstrate that their device meets specific safety and performance characteristics and has been designed and manufactured in accordance with the Essential Principles.

5 Steps to Obtaining ISO 13485:2016 Certification

For most medical device manufacturers, the roadmap to market will start with ISO 13485:2016 certification. Obtaining an ISO 13485:2016 certificate is evidence that the Quality Management System in place is compliant with international standards and is a key component of a registration package with the regulators.